The direct singeing system forms the technological basis of all osthoff-senge singeing machine.

The direct, very intensive flame, the short contact time between flame and free-guided fabric, the ignition flame temperature necessary for the vaporization of polyester and the various singeing positions represent the decisive advantages of the osthoff-senge singeing system.

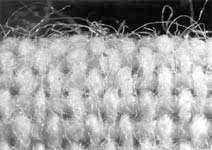

Before Singeing

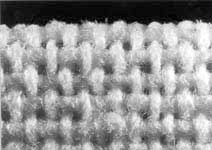

After Singeing

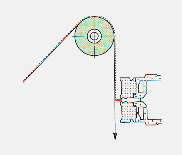

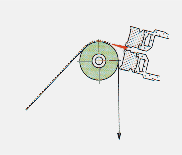

Onto free guided fabric

Flame meets right-angle onto dense woven fabric freely guided between 2 rollers, recommended for natural fibres and blends weighing more than 125g/m².

Singeing onto free-guided fabric

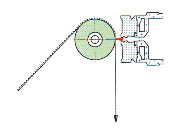

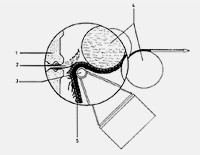

Onto water cooled roller

Flame meets right-angle onto the fabric bended over a water cooled roller. Recommended for fabrics of temperature sensitive fibres, those of open-weave, blended ones weighing less than 125g/m².

Singeing onto a cooled roller

Tangential singeing

Flame passes tangentially over the fabric bended over a water cooled roller recommendable for fabrics which cannot tolerate direct exposure to flame and for repair of filamentation.

Tangential singeing

Flame shearing

Flame passes tangentially over the fabric bended over a singeing sword, with minimized contact time, singeing effect on fibre tip only.

Flame shearing